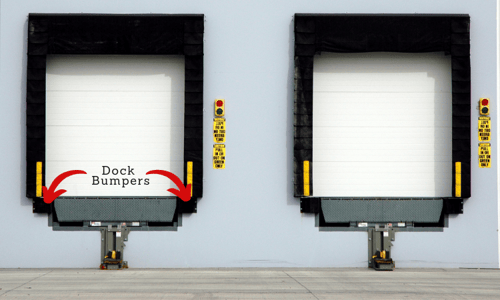

Safety products such as dock bumpers help ensure longevity for your building and its dock bays. Once a small crack or crevice forms on the exterior of the building, it doesn’t take much for it to grow – in size and in cost to repair. Without dock bumpers, your facility is at risk of damage each and every time a trailer backs into your loading dock.

Dock bumpers are one of the least recognized but most valuable pieces of dock equipment you can install on your dock, warehouse, or other areas of your business. They can absorb up to 80% of impact and shock from trucks, train cars, and forklifts, protecting your building, dock, and other workplaces from damage and reducing repair and replacement costs. They also can protect forklift drivers, truckers, and other workers from the jilting of collisions, reducing the risk of injuries.

→ Suggested Read: What is a Loading Dock Leveler (Dock Plate)? ←

Choosing The Right Dock Bumper for Your Loading Dock

Do you know which kind of loading dock bumper your facility needs? It is important that you choose the right type for the job since these are such an important line of defense.

The kind you need depends mainly on the type of work you do, and the models of trailers you work with. There are several basic types of industrial bumpers, including molded, laminated, and steel face, all of which come in a variety of shapes and sizes.

1. Steel Face Dock Bumpers: For Heavy-Duty Applications

Because of the steel face, trailers can rub against the bumpers without pulling and tearing on the rubber buffer, and the impact to the building is minimized. You can make your decision based on how busy your dock is, or how likely it is that there would be a collision involving any type of trailer or loading dock equipment. The added layer of protection keeps the bumpers in good shape while also preventing trailer damage to the building. Steel face loading dock bumpers have the greatest wear capabilities -up to four times the protection of a laminated bumper.

Steel Face Dock Bumper

Steel Face Dock Bumper

2. Laminated Dock Bumpers: For Medium-Duty Applications

They offer more shock absorption through thicker pads and are they are made from recycled truck tires cut to size and held together with steel rods and bookended with steel plates. They have a mid-range of wear capacity and flexibility in thickness, length, and height. They’re popular in loading docks with dock levelers (pit-style levelers) and edge-of-dock levelers and provide long-lasting protection for high-traffic dock operations. To accommodate these levels of impact, steel face bumpers may be best as laminated bumpers aren’t ideal for operations that work with heavier equipment that rides up and down on the dock as it’s loaded. The same goes for businesses using yard jockey trucks or declining loading dock approaches.

3. Rubber Dock Bumpers: For Low-Duty Applications

Molded rubber dock bumpers offer protection for low-traffic loading docks and in-plant wall protection from forklifts and other material-handling vehicles. As the name implies, rubber dock bumpers are made of rubber, but not just any rubber, many of them are made from recycled truck tires, so they are already built from some of the toughest materials that have proven strength and protective absorptive abilities. One of the biggest benefits of rubber dock bumpers is that they can be installed anywhere where protection from impact is needed. They are the most attractive style, but they are easier to chip or gouge than other types of bumpers. The obvious place to protect from impact is the dock bay, but they also can go along walls to protect forklifts, in warehouse doorways, and even near light fixtures.

Rubber Dock Bumpers

Rubber Dock Bumpers

4. Custom Dock Bumpers

Today’s facilities may need larger bumpers or models with deeper projections that offer greater protection. In the past, most bumpers were 10 by 14 inches with a 4-inch projection. Lengths can be adjusted to suit a wide range of applications. Nowadays, dock bumpers come in a variety of sizes with 4 and 6-inch projections and 6, 10, 12, 20, 24, and 36-inch heights.

We can create custom-raised dock bumpers to prevent damage to the trucks and the building when the trailer height does not match the natural height of the bumpers on the loading dock. If you require a more complex solution like an extra length or extra thick dock bumper, we can make it happen.

→ Suggested Read: Quick Guide: What is a Dock Leveler? ←

Choosing the right bumper is important to keep your facility protected against harm. Just because a laminated bumper with a 6-inch projection works for one of your facilities doesn’t mean it’ll work for another that handles different types of loads. There is no single best loading dock bumper that offers the right projection for all types of facilities.

For facilities where trailers are expected to jostle up and down during the loading process, bumpers can also be installed vertically or horizontally.

Call and discuss your needs with one of our dedicated and knowledgeable staff members today.

If you are planning the purchase of loading dock bumpers and want more information on how to choose the best one for your application, contact us today. We’ve been serving the Central Jersey area for over 47 years. Call 908-722-5785 or email us at comm@overheaddoorco.com

→ Suggested Read: Sealing Systems for Loading Docks: Dock Seals & Dock Shelters ←