A dock leveler is a piece of equipment that is usually either mounted to the dock face or recessed into a pit at a loading dock door creating a bridge between a building and a transport vehicle.

Table of Contents:

Part 1: The most common types of dock levelers include:

1. Pit Levelers

1.1 Mechanical Dock Levelers

1.2 Air Dock Levelers

1.3 Hydraulic Dock Levelers

1.4 Vertical Dock Levelers

2. Rail Dock Levelers

3. Edge of Dock Levelers

Part 2: The dock leveler's common terms and definitions.

Part 3: Difference between a truck leveler and a dock leveler

Part 1: Most Common Types of Dock Levelers:

Discover the most common types of dock levelers, and keep an eye out for unique designs exclusive to specific manufacturers.

1. Pit Levelers

Situated in a recessed concrete opening by the dock door of a building, this kind of dock leveler, also known as dock plate, falls into three main sub-categories of such pit levelers:

1.1 Mechanical Pit Leveler: Referred to as a mechanical dock leveler, this type is the most prevalent within the pit leveler category and usually comes with a lower cost. Operating with a mechanical spring system, this style is generally "upward biased," where the spring consistently urges the leveler deck to rise. No electrical power source at the dock is needed for this mechanical leveler. However, servicing and maintaining these levelers can be comparatively more expensive throughout their lifespan.

Mechanical Pit Leveler (also Known as Mechanical Dock Leveler)

Mechanical Pit Leveler (also Known as Mechanical Dock Leveler)

1.2 Air Pit Leveler: Also identified as an air-dock leveler or dock plate, this variety employs a pneumatic bag system to elevate and lower the leveler deck. An electrical power source is necessary, either directly at the dock or nearby. Typically, a standard 110v power source is used. While these levelers are generally somewhat pricier than their mechanical counterparts, they may entail lower service and maintenance needs in comparison.

Air Pit Leveler (Also Known as Air-Dock Leveler)

Air Pit Leveler (Also Known as Air-Dock Leveler)

1.3 Hydraulic Pit Leveler: Also known as a hydraulic dock leveler or dock plate, this type stands out as the most adaptable among pit-style levelers. Utilizing a hydraulic cylinder for deck movement and typically another for lip operation, these levelers can be configured in various ways and powered by anything from 110V single phase to 575V three-phase. The hydraulic choice offers greater flexibility compared to mechanical or air dock levelers and usually incurs lower service and maintenance expenses.

Hydraulic Pit Leveler (Also Known as Hydraulic Dock Leveler)

Hydraulic Pit Leveler (Also Known as Hydraulic Dock Leveler)

1.4 Vertical Dock Leveler: A vertical dock leveler is precisely as its name suggests - a dock leveler stored in a vertical position. The advantage of this design is evident: it enables the storage of the leveler inside the building, allowing the dock door to close directly on concrete instead of over the leveler, as with a pit leveler. This setup enhances environmental control within the building. Vertical levelers are commonly employed in food service applications or locations where washdown is a concern. They are typically hydraulically operated and either pit or shelf-mounted.

2. Rail Dock Levelers

Rail Dock Leveler: These levelers present a modification of the vertical leveler and are designed for servicing rail cars. Typically installed on a sliding rail, they can move horizontally along the rail track. Their movement along the track can be either manual or hydraulic, and the levelers themselves are generally operated hydraulically.

3. Edge of Dock (EOD)

Edge of Dock (EOD) Leveler: This is a simple device that is usually mechanically operated but may be pneumatically or hydraulically operated. It is often found mounted on the exterior wall of a building with an integral loading dock bumpers set but may also be pit mounted. The EOD leveler has a limited vertical operating range and is geared toward applications where the transport vehicle bed is at, or very near, the floor level of the building (dock level). These units are generally inexpensive when compared to a pit or vertical dock leveler but may be considered an upgrade from portable dock boards as they are fixed to the dock face and have some form of lift assistance (mechanical, air, or hydraulic). A recommended normal working range of an EOD is typically +/- 3 inches.

→ Suggested Article: Benefits of Installing a Hydraulic Edge-of-Dock Leveler ←

Part 2: Dock Leveler Common Terms and Definitions

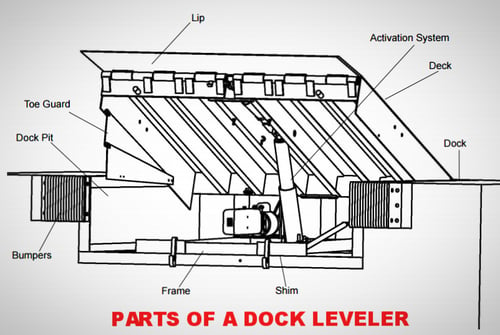

- Activation System: It is responsible for the motion of the dock leveler and may or may not necessitate external power connections. Common activation systems include mechanical (springs), pneumatic (air bladders), and hydraulic.

- Attachments: This term refers to tools that can be affixed to a fork truck for load handling purposes. Accessories like clamps, slip sheet forks, and carpet poles can impact capacity and should be taken into account when choosing a dock leveler.

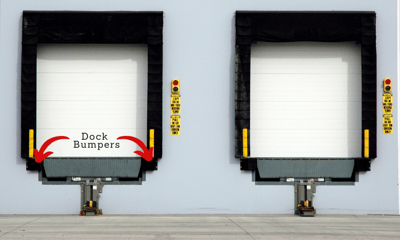

- Bumpers: These are used to shield the building, dock leveler, or vehicle restraint from contact and potential damage by the transport vehicle. Typically composed of rubber, the sizes and projections of loading dock bumpers vary, depending on factors like the vehicles served and driveway slope.

- Capacity: The manufacturer's capacity tag may not accurately represent the gross roll-over load for a particular dock leveler. Capacity is the load rating deemed suitable by the dock leveler manufacturer based on the user's application characteristics. This required capacity is determined by considering the GVW (Gross Vehicle Weight) and applying a complexity factor, which takes into account various factors such as the heaviest forklift and load, number of cycles, speed, life expectancy, loading slope, type of lift trucks, attachments, lip length, and more. To determine the necessary dock leveler capacity for a specific application, it's advisable to consult the authorized sales representative of the manufacturer.

- Deck: The deck assembly constitutes the primary component of the structure that vehicles drive over. Decks commonly feature an anti-skid surface like a tread plate for traction at different working angles. The assembly pivots at the rear end of the dock leveler, farthest from the transport vehicle, and has a hinged lip attached at the opposite end.

- Dock: This is the area of a building designated for loading and/or unloading transport vehicles.

- Dock Level: This term involves the vertical level aligned with the building's floor surface.

- Dock Pit: The pit is the recessed opening in the building’s floor designed to house the pit dock leveler. Typically, the pit's edges are bordered with structural steel angles embedded in the concrete.

- Frame: The frame assembly is the supporting structure for a dock leveler.

- Gross Vehicle Weight (GVW): The GVW represents the total weight of both the material handling equipment (such as a lift truck or pallet jack) and the load. Essentially, it is the maximum weight being transferred across the dock leveler.

- Lip: The lip assembly is usually pivotally attached to the deck assembly moving from a vertically stored position to a position resting on the floor of the transport vehicle. Lips usually feature a tread plate material similar to the deck.

- Load: The load refers to the weight of a typical individual pallet on a transport vehicle. In standard capacity calculations, there is a maximum limit of twenty loads per transport vehicle.

- Shift: This term denotes the operational shift at the building. For capacity calculation purposes, a standard calculation would involve a maximum of eight trailers per shift.

- Shim: These are steel plates utilized to assist in leveling pit-mounted dock levelers. Shims can be positioned beneath the frame structure and welded in place to establish a structural load path to the building's foundation.

- Toe Guard: It is a protective shield affixed flush to the side of a deck assembly, offering toe protection when the dock leveler is positioned above dock level.

- Transport Vehicle: It refers to a cargo-carrying vehicle like a truck, semi-trailer, trailer, or railcar.

- Working Range: It is the suggested vertical travel range above and below dock level suitable for loading and unloading activities.

Part 3: Difference Between a Truck Leveler and a Dock Leveler

A truck leveler elevates the front of the truck to achieve a balanced stance, while the dock leveler (dock plate) serves as a bridge between the truck and the loading dock, filling the gap and enhancing the safety of material loading/unloading. When a dock is too high or low for a conventional dock leveler, a truck leveler is employed to align with the loading dock's height.

Truck Leveler. Photo Credit: Serco Loading Dock Solutions

Truck Leveler. Photo Credit: Serco Loading Dock Solutions

Reach out to us for all your loading dock equipment needs, including top-notch dock levelers. With over 50 years of unparalleled expertise in Central Jersey, our dedicated team is here to ensure your loading dock operates seamlessly and efficiently.

Your satisfaction is our commitment, and we're ready to go above and beyond to exceed your expectations. Contact us today for unparalleled service and excellence that stands the test of time.

Call: 908-722-5785 or email comm@overheaddoorco.com

Suggested Read: → Learn About Our Loading Dock Equipment Preventive Maintenance Programs ←

Tags: dock leveller, dock levelling, dock plate, edge of dock, dock leveler repair, dock plate repair, dock plate service, dock leveler service